Welcome to the future of manufacturing!

Today, we’re diving into the world of advanced machining solutions for rapid prototyping. We’ll explore how these tools can transform your raw ideas into tangible products.

From the early prototype stages to full-scale production, advanced machining plays a pivotal role. Strap in as we demystify this aspect of modern manufacturing, whether you’re an industry veteran or a curious newcomer.

The Power of Rapid Prototyping

Rapid prototyping is a powerful innovation in the realm of manufacturing. It allows designers to turn their conceptual designs into physical prototypes. This is by leveraging cutting-edge prototyping technologies and advanced machining techniques.

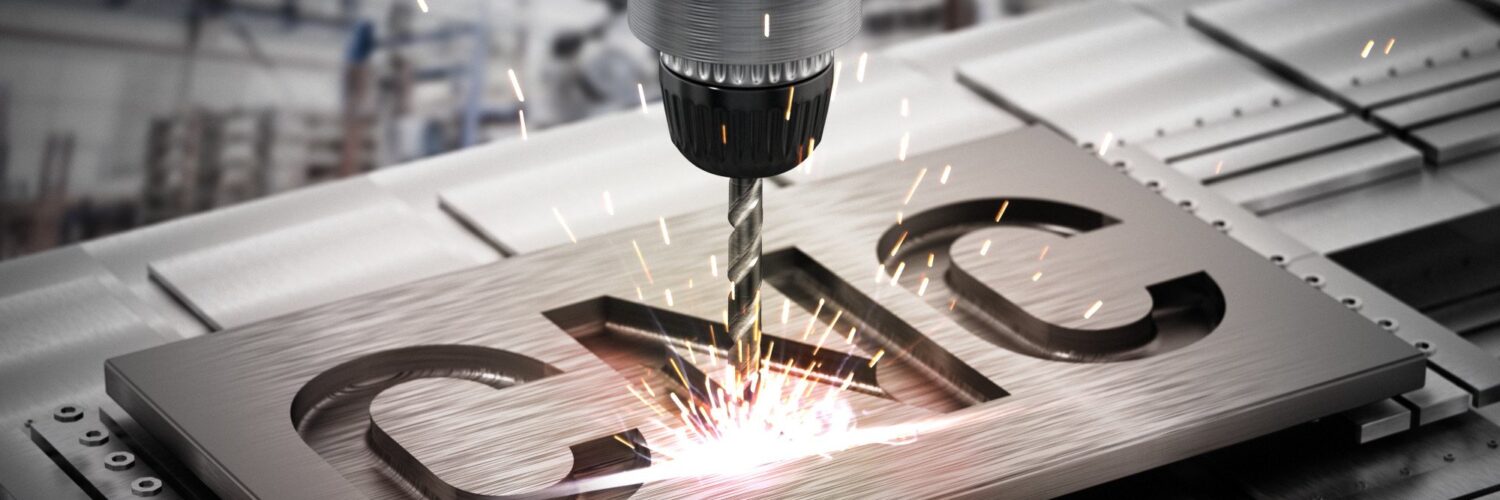

This expedites the product development process. It enables quick identification and rectification of design flaws. With CNC machining, intricate and precise prototypes can be produced with high repeatability.

In essence, rapid prototyping empowers manufacturers to do the following:

- streamline design workflow

- speed up time-to-market

- enhance product quality

- precision engineering

Understanding Advanced Machining Solutions

These represent a paradigm shift in the world of production and manufacturing. Utilizing cutting-edge technologies enables precision. This applies to producing prototypes and final products.

This includes the following:

- high-speed CNC

- electrical discharge machining

- laser-assisted manufacturing

The technology opens up new possibilities for complex designs and materials. This is while ensuring high product quality and operational efficiency. These techniques can handle a wide range of materials.

This is from metals to polymers and even ceramics. These all come with precision and repeatability.

Advanced machining solutions are transforming the way we prototype. It also transforms the way we manufacture products.

The Journey From Prototype to Production

This process is a critical yet exciting phase in product development. It is here that advanced machining solutions shine. By utilizing sophisticated prototyping technologies, this process becomes seamless and efficient.

The prototypes, once refined and finalized, are ready for production. These ensure the accurate reproduction of the prototype’s design. It maintains the quality and precision of the initial prototypes.

This seamless transition does the following:

- ensures the design’s integrity

- accelerates production timeline

- upholds high standard

The Role of Advanced Machining

This is a game-changer in the modern manufacturing landscape. It facilitates the production of intricate designs with high accuracy.

This is due to its superior precision and repeatability. This contributes to product quality and consistency.

Advanced machining techniques streamline manufacturing. This reduces time, effort, and cost. It includes creating precise prototypes and executing large-scale production.

Moreover, they enable effective material use. This promotes sustainability in the long run. Incorporating these solutions has become indispensable in today’s innovation-driven manufacturing industries.

All About Advanced Machining Solutions

So, let’s bring it all together. We can take a product from an idea to reality with super speed. This is with rapid prototyping and advanced machining.

This tech lets us make better stuff in less time and is good for all kinds of materials. It saves time and money and helps us care for our planet better. In short, you must consider using this tech if you’re making things.

We’ve got you covered if you want to explore the best topics. Check out some of our other blogs today!

Add comment